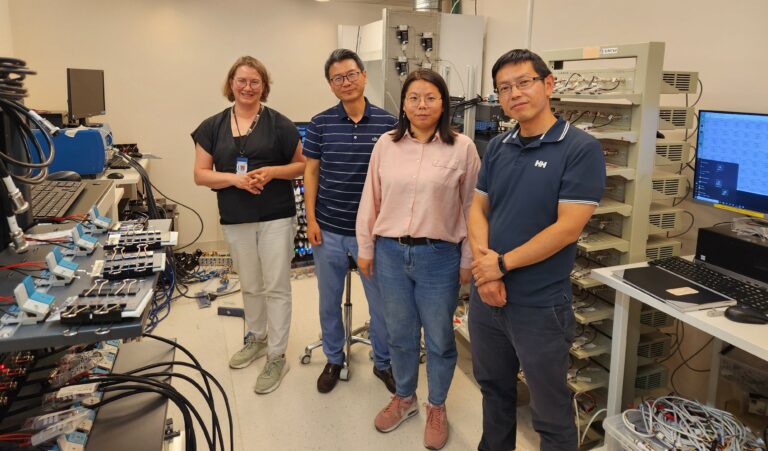

BIOANODE Kick-off Meeting in Trondheim with SINTEF Energy & NTNU

We had a kick-off meeting for our BIOANODE project (Conversion of BIOmass resource from forest industry into hard carbons as greener sodium ion battery ANODE) at NTNU in Trondheim on

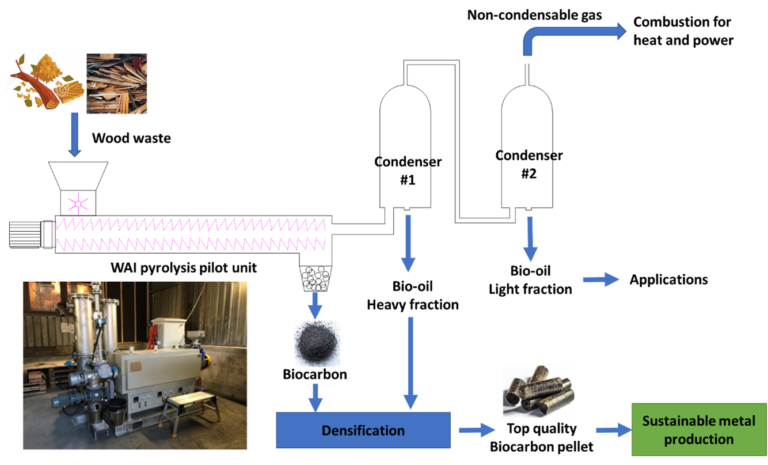

WAI Environmental Solutions provides innovative solutions to improve sustainability of the high carbon emission companies and the waste management industry.

With superior physical and thermal strength, WAI Biocarbon is formulated for meeting long-term needs in metallurgical industries.

Designed and engineered for energy storage applications, primarily in the field of Na-ion battery. From forest residue, WAI produces advanced carbon materials that can be used for hard carbon production.

Innovative single-cell protein, a high-quality and sustainable protein to meet the increasing feed demand for aquaculture, pets, and livestock

WAI’s brand name for individual biocarbon production facilities which use biocarbon to replace fossil-carbon as a reducing agent, producing metallurgical biocarbon and thermal- and electrical-energy.

WAI Environmental Solutions AS provides innovative solutions to improve sustainability of the high carbon emission companies and the waste management industry. We develop and implement environmental technologies for organic waste valorisation, renewable energy and biochar production, hazardous waste treatment and wastewater treatment. We truly believe great opportunities lie in closing the circular economy gaps. Our solutions are based on low temperature belt dryer, pyrolysis, anaerobic digestion, and biofilm-based wastewater treatment technologies.

WAI Environmental Solutions AS provides innovative solutions to improve sustainability of the high carbon emission companies and the waste management industry. We develop and implement environmental technologies for organic waste valorisation, renewable energy and biochar production, hazardous waste treatment and wastewater treatment. We truly believe great opportunities lie in closing the circular economy gaps. Our solutions are based on low temperature belt dryer, pyrolysis, anaerobic digestion, and biofilm-based wastewater treatment technologies.

Industrial plants called CarbonWorks® use biocarbon to replace fossil-carbon as a reducing agent, producing metallurgical biocarbon and thermal- and electrical-energy.

Our pyrolysis systems have been installed in five countries with largest handling capacity of 5 ton per hour. The systems work at a wide range of temperatures with many types of feedstocks.

We had a kick-off meeting for our BIOANODE project (Conversion of BIOmass resource from forest industry into hard carbons as greener sodium ion battery ANODE) at NTNU in Trondheim on

TOPBIO project (Valorisation of wood waste into TOP quality BIOcarbon for sustainable metallurgical industries) is a 2.5-year regional innovation project funded by Regional Research funds (RFF) Vestfold og Telemark. WAI