CarbonWorks® Biocarbon Production

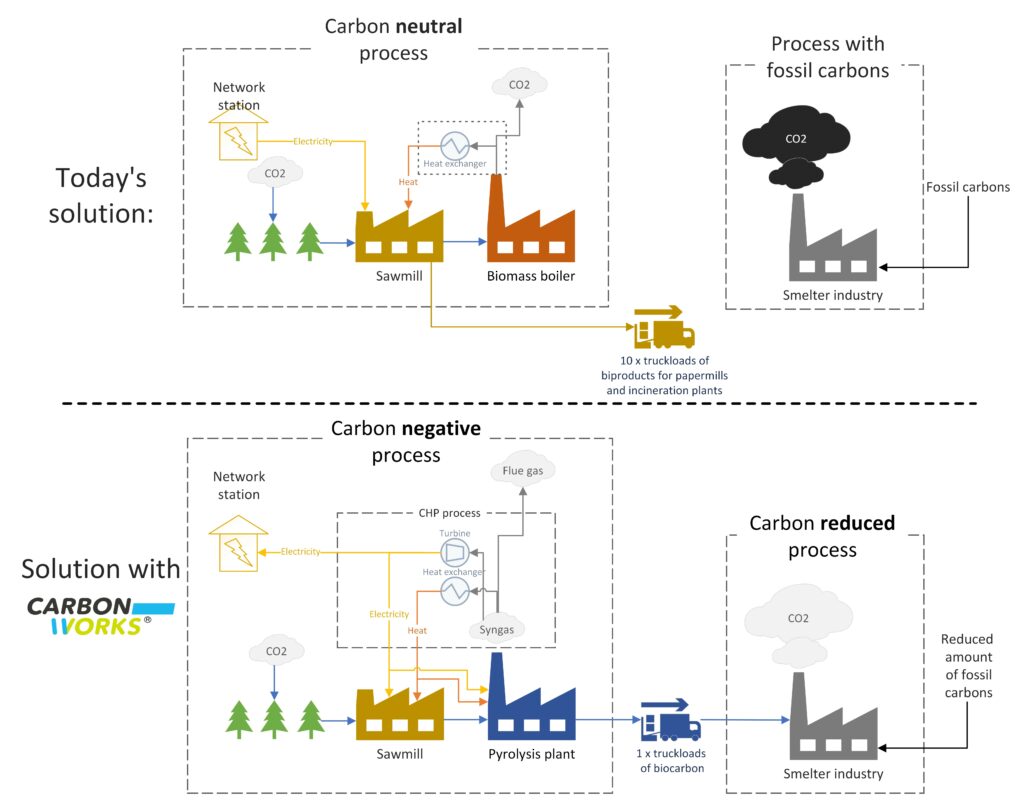

CarbonWorks® is WAI’s brand name for individual biocarbon production facilities.

- feedstock storage and pre-treatment

- pyrolysis

- syngas combustion and heat recovery

- syngas combustion and heat recovery

- flue gas treatment

- biocarbon formulation stages

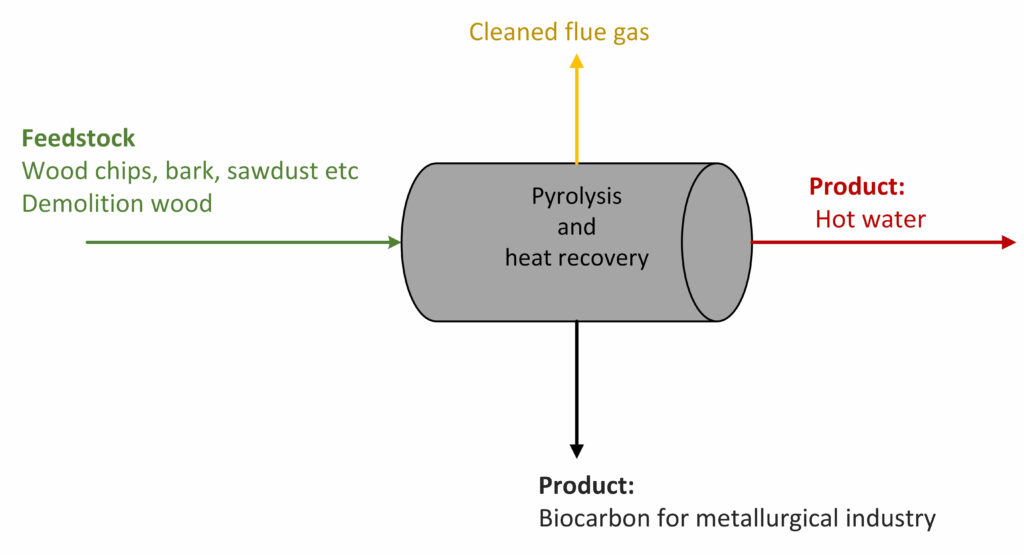

The CarbonWorks® process can in-take following feedstocks: forest residue (especially sawmill by-products, such as sawdust, wood chips, bark and shavings), forest logging residues, demolition wood, garden waste, pulp & paper and biorefinery waste.

Besides biocarbon, CarbonWorks® plants also produce renewable energy in the forms of hot water, steam, electricity.

For electricity production, CarbonWorks® engages an Organic Ranking Cycle (ORC) technology.

CarbonWorks® plants will be built according to all applicable laws, regulations and standards and addressing all relevant EHS (environment, health and safety) measures.

CarbonWorks® meets all emission requirements using BAT (Best Available Techniques) for cleaning flue gas.

A standard CarbonWorks® plant can:

process 60,000 tons of sawmill by-products and waste wood annually,

produce 10,000 tons of biocarbon pellets and 55 GWh renewable energy annually,

reduce 33,000 tons CO2 emissions in metallurgical industry annually,

meet new requirements for emissions to air,

reduce 90% truck traffic from sawmill by converting bulky by-products to dense biocarbon pellets,

save sawmill investment on new boilers by supplying hot water to sawmills,

create higher value for sawmill by-products and waste wood, and realize material recycling.